Sign up for a full digest of all the best opinions of the week in our Voices Dispatches email Sign up to our free weekly Voices newsletter

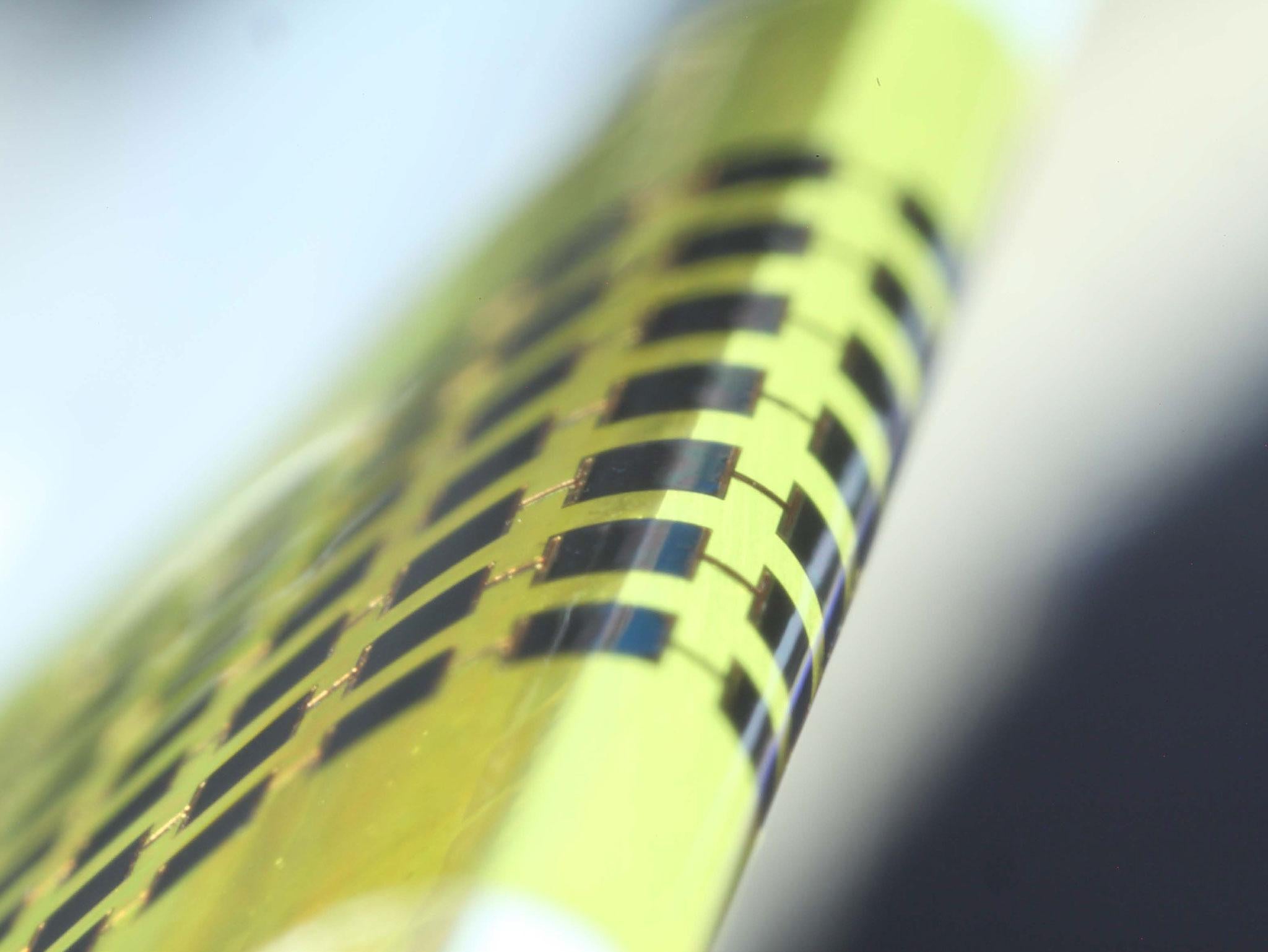

Solar panels so flexible and thin that they can be wrapped around the frame of a pair of glasses have been developed by scientists in a potential breakthrough for wearable electronics.

The panels, developed by a team of researchers in South Korea, are just a single micrometre across – much thinner than the average human hair or a coat of paint, which are both typically about 100 micrometres.

These are hundreds of times thinner than standard solar panels and three to four times thinner than most of the slimmest solar cells currently available.

Professor Jongho Lee, an engineer at the Gwangju Institute of Science and Technology, said that their panels were “less fragile under bending, but perform similarly or even slightly better” to panels 3.5 micrometres across.

The researchers said the new material was easily flexible enough to wrap around a pencil. And in tests they found it would still work when wrapped around something just 1.4mm wide.

It is thought the panels could be used to provide power for smart glasses or incorporated into clothing to power wearable technology, which is often limited by the size and weight of the battery.

The scientists, who published their findings in the journal Applied Physics Letters , wrote that they had made the ultra-thin solar cells using a semiconductor, gallium arsenide.

Show all 20 1 /20Science news in pictures Science news in pictures Pluto has 'beating heart' of frozen nitrogen Pluto has a 'beating heart' of frozen nitrogen that is doing strange things to its surface, Nasa has found. The mysterious core seems to be the cause of features on its surface that have fascinated scientists since they were spotted by Nasa's New Horizons mission. "Before New Horizons, everyone thought Pluto was going to be a netball - completely flat, almost no diversity," said Tanguy Bertrand, an astrophysicist and planetary scientist at NASA's Ames Research Center and the lead author on the new study. "But it's completely different. It has a lot of different landscapes and we are trying to understand what's going on there."

Getty

Science news in pictures Over 400 species discovered this year by Natural History Museum The ancient invertabrate worm-like species rhenopyrgus viviani (pictured) is one of over 400 species previously unknown to science that were discovered by experts at the Natural History Museum this year

PA

Science news in pictures Jackdaws can identify 'dangerous' humans Jackdaws can identify “dangerous” humans from listening to each other’s warning calls, scientists say. The highly social birds will also remember that person if they come near their nests again, according to researchers from the University of Exeter. In the study, a person unknown to the wild jackdaws approached their nest. At the same time scientists played a recording of a warning call (threatening) or “contact calls” (non-threatening). The next time jackdaws saw this same person, the birds that had previously heard the warning call were defensive and returned to their nests more than twice as quickly on average.

Getty

Science news in pictures Turtle embryos influence sex by shaking The sex of the turtle is determined by the temperatures at which they are incubated. Warm temperatures favour females. But by wiggling around the egg, embryos can find the “Goldilocks Zone” which means they are able to shield themselves against extreme thermal conditions and produce a balanced sex ratio, according to the new study published in Current Biology journal

Ye et al/Current Biology

Science news in pictures Elephant poaching rates drop in Africa African elephant poaching rates have dropped by 60 per cent in six years, an international study has found. It is thought the decline could be associated with the ivory trade ban introduced in China in 2017.

Reuters

Science news in pictures Ancient four-legged whale discovered in Peru Scientists have identified a four-legged creature with webbed feet to be an ancestor of the whale. Fossils unearthed in Peru have led scientists to conclude that the enormous creatures that traverse the planet’s oceans today are descended from small hoofed ancestors that lived in south Asia 50 million years ago

A. Gennari

Science news in pictures Animal with transient anus discovered A scientist has stumbled upon a creature with a “transient anus” that appears only when it is needed, before vanishing completely. Dr Sidney Tamm of the Marine Biological Laboratory could not initially find any trace of an anus on the species. However, as the animal gets full, a pore opens up to dispose of waste

Steven G Johnson

Science news in pictures Giant bee spotted Feared extinct, the Wallace's Giant bee has been spotted for the first time in nearly 40 years. An international team of conservationists spotted the bee, that is four times the size of a typical honeybee, on an expedition to a group of Indonesian Islands

Clay Bolt

Science news in pictures New mammal species found inside crocodile Fossilised bones digested by crocodiles have revealed the existence of three new mammal species that roamed the Cayman Islands 300 years ago. The bones belonged to two large rodent species and a small shrew-like animal

New Mexico Museum of Natural History

Science news in pictures Fabric that changes according to temperature created Scientists at the University of Maryland have created a fabric that adapts to heat, expanding to allow more heat to escape the body when warm and compacting to retain more heat when cold

Faye Levine, University of Maryland

Science news in pictures Baby mice tears could be used in pest control A study from the University of Tokyo has found that the tears of baby mice cause female mice to be less interested in the sexual advances of males

Getty

Science news in pictures Final warning to limit "climate catastrophe" The Intergovernmental Panel on Climate Change has issued a report which projects the impact of a rise in global temperatures of 1.5 degrees Celsius and warns against a higher increase

Getty

Science news in pictures Nobel prize for evolution chemists The nobel prize for chemistry has been awarded to three chemists working with evolution. Frances Smith is being awarded the prize for her work on directing the evolution of enzymes, while Gregory Winter and George Smith take the prize for their work on phage display of peptides and antibodies

Getty/AFP

Science news in pictures Nobel prize for laser physicists The nobel prize for physics has been awarded to three physicists working with lasers. Arthur Ashkin (L) was awarded for his "optical tweezers" which use lasers to grab particles, atoms, viruses and other living cells. Donna Strickland and Gérard Mourou were jointly awarded the prize for developing chirped-pulse amplification of lasers

Reuters/AP

Science news in pictures Discovery of a new species of dinosaur The Ledumahadi Mafube roamed around 200 million years ago in what is now South Africa. Recently discovered by a team of international scientists, it was the largest land animal of its time, weighing 12 tons and standing at 13 feet. In Sesotho, the South African language of the region in which the dinosaur was discovered, its name means "a giant thunderclap at dawn"

Viktor Radermacher / SWNS

Science news in pictures Birth of a planet Scientists have witnessed the birth of a planet for the first time ever. This spectacular image from the SPHERE instrument on ESO's Very Large Telescope is the first clear image of a planet caught in the very act of formation around the dwarf star PDS 70. The planet stands clearly out, visible as a bright point to the right of the center of the image, which is blacked out by the coronagraph mask used to block the blinding light of the central star.

ESO/A. Müller et al

Science news in pictures New human organ discovered that was previously missed by scientists Layers long thought to be dense, connective tissue are actually a series of fluid-filled compartments researchers have termed the “interstitium”. These compartments are found beneath the skin, as well as lining the gut, lungs, blood vessels and muscles, and join together to form a network supported by a mesh of strong, flexible proteins

Getty

Science news in pictures Previously unknown society lived in Amazon rainforest before Europeans arrived, say archaeologists Working in the Brazilian state of Mato Grosso, a team led by archaeologists at the University of Exeter unearthed hundreds of villages hidden in the depths of the rainforest. These excavations included evidence of fortifications and mysterious earthworks called geoglyphs

José Iriarte

Science news in pictures One in 10 people have traces of cocaine or heroin on fingerprints, study finds More than one in 10 people were found to have traces of class A drugs on their fingers by scientists developing a new fingerprint-based drug test. Using sensitive analysis of the chemical composition of sweat, researchers were able to tell the difference between those who had been directly exposed to heroin and cocaine, and those who had encountered it indirectly.

Getty

Science news in pictures Nasa releases stunning images of Jupiter's great red spot The storm bigger than the Earth, has been swhirling for 350 years. The image's colours have been enhanced after it was sent back to Earth.

Pictures by: Tom Momary

They were then stamped on to a flexible material, avoiding the need for an adhesive that would add to its thickness. The cells were “cold-welded” to an electrode.

While some other researchers have made solar panels of around one micrometre thick before, they did so using a different technique, called etching.

Professor Lee’s team believes that their method of transfer printing could enable highly flexible photovoltaic cells to be made with a smaller amount of materials.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies